Induction Cap Sealing – An Efficacious Solution for Pharmaceuticals

Induction Cap Sealing – An Efficacious Solution for Pharmaceuticals

Pharmaceutical products are formulated in various dosage forms – solids (powders, tablets, capsules), liquids (solutions, syrups, suspensions, emulsions), semi-solids (creams, ointments, lotions), etc. based on therapeutic use and route of administration.

The packaging of the product is designed with the aim of retaining the potency and efficacy of the drug throughout the shelf life. The general rule is that the drug should retain 90% or more of its potency at expiration date. Exposure to unwanted contaminants can affect the potency and efficacy of the drug and also accelerate rate of deterioration.

The products are at constant risk of exposure to contaminants during their entire supply chain journey.

-

Chemical contamination can be caused by vapor, moisture, gases, etc. Exposure to moisture or vapor may cause physical changes in the product such as color, texture, taste, hardness, viscosity, etc. These indicate that the product is unfit for consumption.

However, sometimes there may be chemical changes with no visual evidence. Chemical degradation leads to loss in potency and efficacy. Moreover it also causes some drugs to produce harmful moieties triggering adverse effects in the patients.

- Biological contamination can be caused by bacteria, fungus, molds, etc. Liquid and semi-solid formulations are more conducive to microbial contamination. Microbial growth increases risk of harmful effects if it is consumed unknowingly.

-

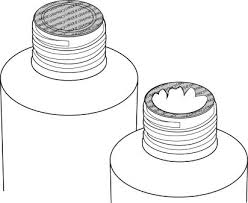

Tampering of pharmaceutical products occur when the original product is removed from the container and substituted with ineffective or spurious one. This poses a grave risk to the unaware consumer.

The challenge posed in pharmaceutical packaging is that it should have no adverse interaction with the product and offer a perfect barrier. Moreover the packaging should be tamper evident which helps the consumer identify whether the product is safe for consumption or application.

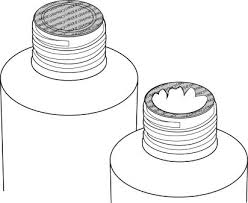

The solution can be found with Induction cap sealing , which provides a seal of aluminum foil covering the entire mouth of the container. This is an effective barrier against contaminants.

The seal even helps to provide tamper evidence. Supply chains and routes from manufacturing to consumers sometimes traverse across regional and national borders. Induction cap sealing is a sturdy packaging that can withstand transport and storage.

Sigma CapSeal, a pioneer in induction cap sealing , has partnered with various Pharma companies to improve the packaging and deliver efficacious products to the consumers.