What is an induction seal check integrity machine and what are its advantages?

What is an induction seal check integrity machine and what are its advantages?

One of the critical aspects of quality control of packaged products is their seal integrity. A compromised seal will lead to product leakage and reduce its shelf-life. If the faulty package is with another bunch of products, it can even damage them.

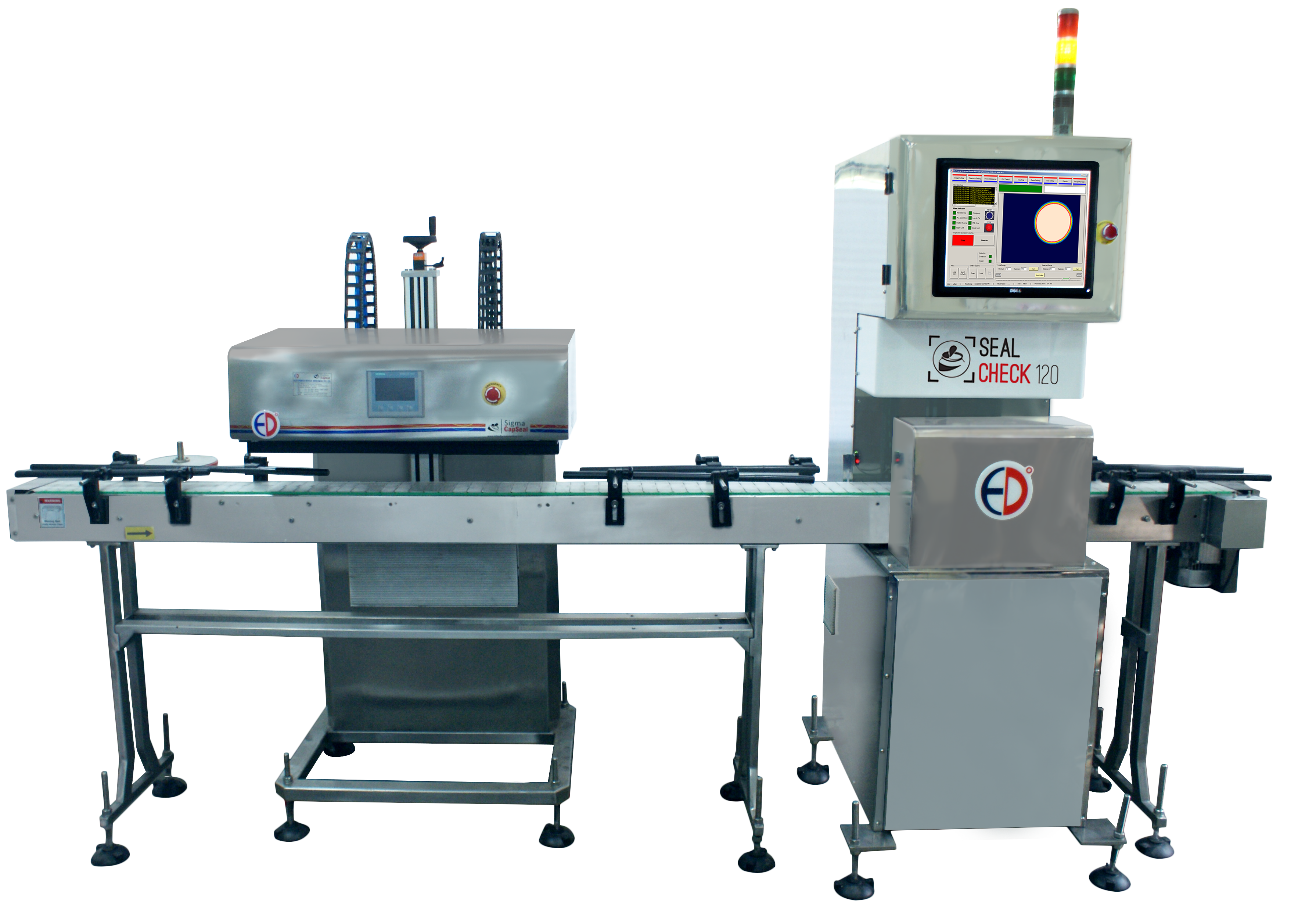

Businesses over the years are continuously adopting innovation to improve their packaging standards. An induction seal check integrity machine is an ideal option to overcome this problem. This article looks at what is an induction seal check integrity machine and how it can benefit you.

Factors that lead to leakage in packaged products

There are several testing techniques and transportation issues that can lead to seal integrity getting compromised. The heating element used to seal products can also lead to this problem. There can be defects or misalignment in regard to ensuring an adequate amount of heat required for sealing packages. The pressure or duration of heating can lead to packaging defects.

It thus becomes essential to check seal integrity comprehensively through equipment that checks leakages. A packaged product with faulty sealing can soil and damage other products in the lot as well. Similarly, if it reaches the hands of the consumers, it can lead to complaints and loss of trust. You cannot afford this to happen as a single complaint will be enough to bring down your reputation in the market.

Testing seal integrity of packaged products

One of the popular product packaging in the manufacturing industry is PET bottles. Plastic bottles and containers are widely used for the packaging of food and beverages, cosmetics, and other consumer products. The seal checking equipment can help you in preventing leakage of containers. An induction seal check integrity machine will also confirm whether products are fit enough for shipping.

Containers with secure sealing can go out of the warehouses without any concern. You can segregate packages with faulty sealing and take corrective steps. It will help you avoid embarrassing situations where your customers receive products with faulty sealing.

An induction seal check integrity machine provides you with accurate readings during the testing process. These machines can even handle the rigours of the industrial production environments and offer the best results. You can get digital machines with a computer interface that make it easy for operators to run them. Your operators do not need to stress much as these machines are easy to operate.

Features of an induction seal check integrity machine

-

Complete quality assurance of packaged products

Identify and fix packaging issues in real-time

Interference and degradation-free testing of products

Tamper-evidence verification

Bottom Line

Induction seal integrity testing of product seals remains a crucial quality control measure for manufacturing businesses. It ensures that products are fit for delivery and consumption. Induction seal check integrity machines have gained much prominence in recent years. If you are looking to improve your manufacturing standards, bringing this equipment into your production environment can benefit you.

Looking for more details on how an induction seal check integrity machine will be beneficial for your business? Contact us today, and our experts will assist you right away. We will also show you a product demo that will help you understand the equipment better.