What is a vision inspection system and what are its advantages?

What is a vision inspection system and what are its advantages?

Vision inspection systems have gained a lot of importance over the years due to increased compliance norms and regulations. You might already be taking care of manufactured products at your production plant. However, it is always better to conduct inspections at regular intervals. Examination of products is not only about checking them from a distance.

When done appropriately, it can help you avoid customer complaints. There can be several minute issues with product packaging, which might be visible to the naked eye or from a distance. Regular inspections help in preventing faulty products from getting out of your warehouse.

A vision inspection system is one such mechanism that can be especially beneficial for your manufacturing plant. This article looks at how it functions and what are its advantages.

What is a vision inspection system?

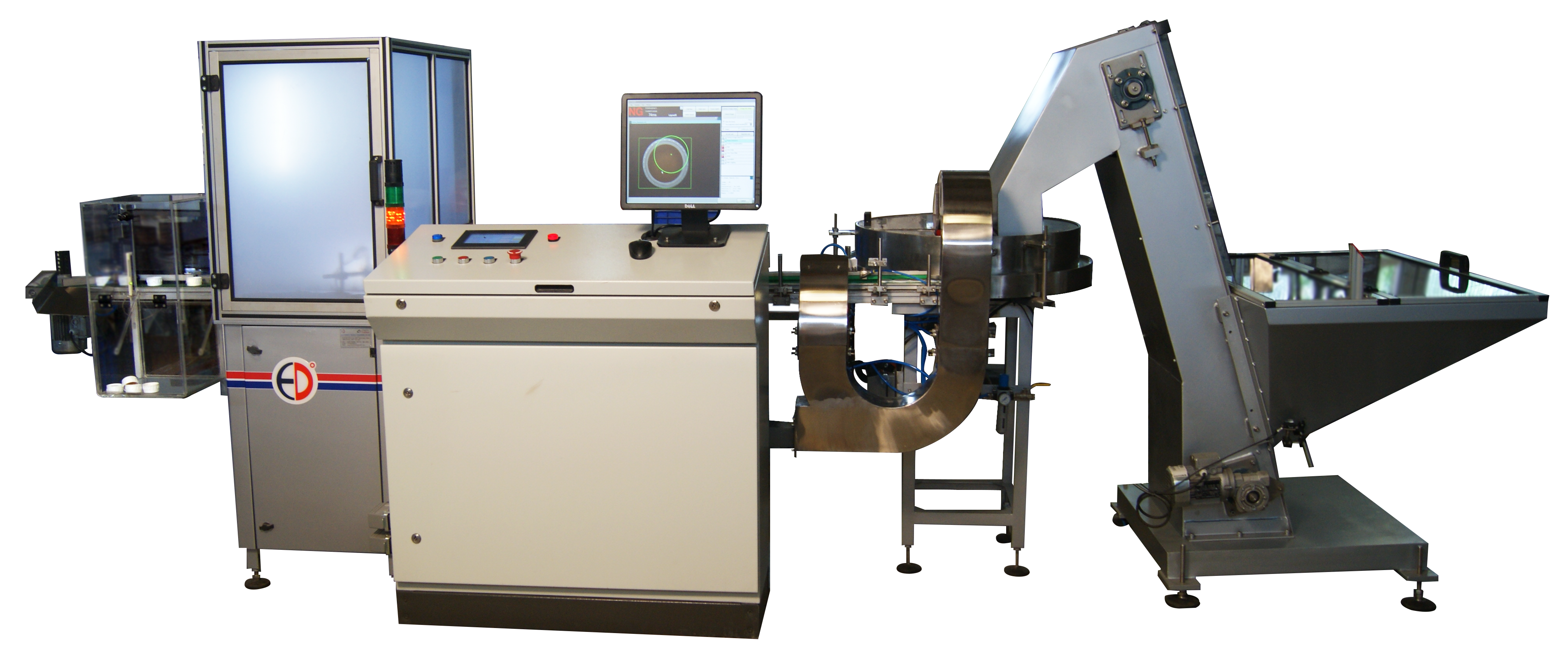

A vision inspection system is also known as a machine vision system. It offers image-basedinspection for equipment. No matter what your manufacturing applications are, you can get an automated inspection process. The technology has been around for many years. In current times, 2D and 3D vision systems are finding wide-ranging use in automated inspections.

Besides regular inspections, there is also quality control and sorting, automated guidance, and a lot more. These inspection systems check the product for contaminants, packaging defects, and other irregularities. One of the examples of inspection includes checking a packaged sauce bottle.

The system would check if the cap has any damage or crack. Similarly, it would inspect if the sealing is appropriate and there are no chances of leakage. The inspection system will also check if the product is complete in all sense for shipping. It happens by ensuring product and packaging information matches and safety lids, rings, and everything else is in place.

How does a vision inspection system function?

Vision inspection systems come with one or multiple cameras, lighting, and video functions. The equipment can measure packaging and assess its shape. They can also sort packages at high speeds. It comes with computer software that captures and processes images during the process.

It has inbuilt intelligence to decide on the outcomes of functions you want to check. Operators can get responses whether to pass or fail a packaged product. You can integrate a vision inspection system in your production line and remain updated at all times.

Industries where vision inspection system is helpful

A vision inspection system is ideal for every industry where quality control is of paramount importance. It can automate and streamline the production process by checking the position of packages.

You can also use the data to improve the process efficiencies of manufacturing lines and related applications. The information can also help you identify issues related to the production line or any other function. It will help you overcome inefficient processes for improved production standards.

As a vision inspection system brings together various technologies, you can customize them based on your business requirements. So, it is beneficial in quality control aspects to design the equipment that meets all your needs. Businesses from industries like food and beverage, packaging, automotive, pharmaceuticals, and many more can use these systems.

Bottom Line

A vision inspection system shows how you can improve the quality control aspects of their business. Besides ensuring higher quality, you can also improve production speeds and reduce costs due to the automation of processes.

If there are any defects in the packaged products, you can detect them early. Those faulty products would not pass into the product assembly. It will help in saving your precious time and money.

At Sigma CapSeal, we have a top-notch vision inspection system that will improve your production standards. Contact us today to know more details.