Seal Integrity Testing Machine - Sigma CapSeal

Seal integrity testing machine is one of the essential equipment in any production environment.It helps you in ensuring that the seals applied to products do not contain any defects. Seals, inmany cases, can develop defects like cut, burn, and leakage. There can also be loose-fitting or noseat at all.

A seal integrity testing machine helps you overcome this problem by detecting products withfaulty seals. It prevents those products from reaching into the hands of customers. So, it helpsmaintain your brand image and reputation in the market.

Types of seal integrity testing machines

The seal integrity testing machine of Sigma CapSeal comes in three variants.

- Seal Check 200 CRC

- Seal Check 120 CT

- Seal Check Pro

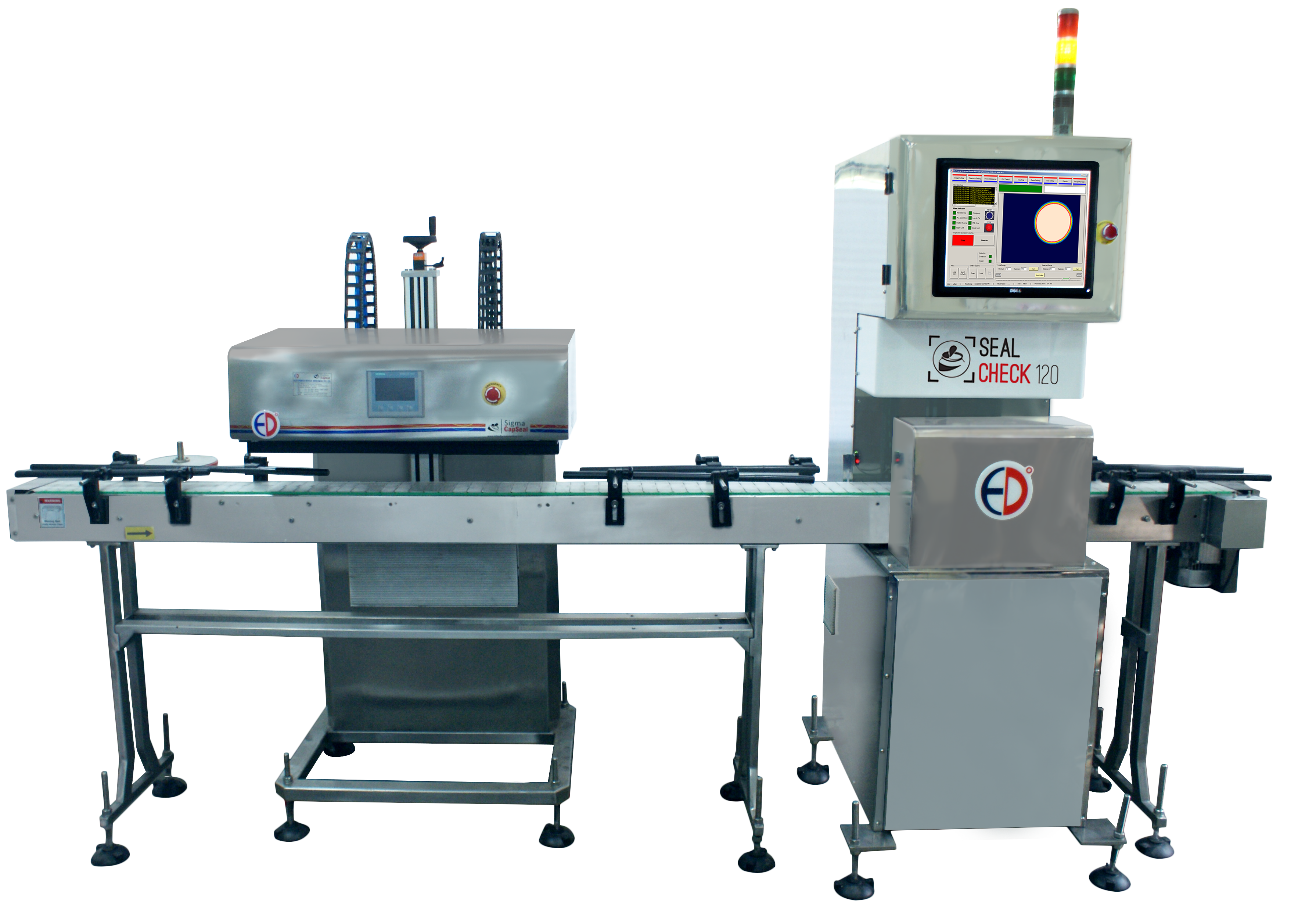

Design and assembly of seal integrity testing machines

These machines have a mechanical and electrical system. The mechanical system comes with acomplete machine cabinet, camera height adjustment, and lockable rejection bin. In the proversion, there is an option to adjust camera height manually. There is also a cabinet for PC andUPS. The electrical system has a PLC, UPS industrial PC with monitor, and other necessaryelectrical components.

Software capabilities of seal integrity testing machines (200CRC/120CT)

- Password protected machines

- 21 CFR compliant

- Audit reports (unalterable)

- Recipe management and loading

- Five-level user management

- Reports (production, alarms, rejection analysis)