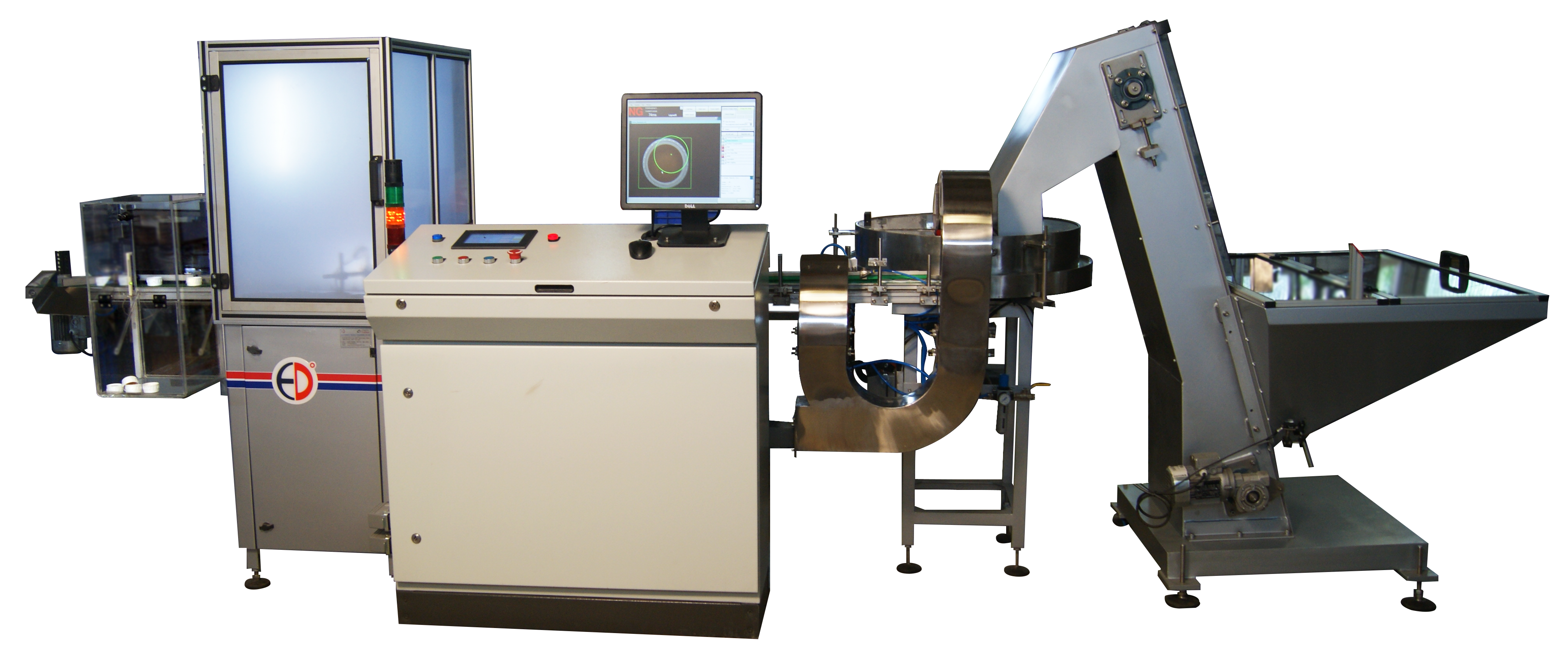

Vision Inspection System- Sigma CapSeal

Vision inspection systems in the packaging manufacturing industry offer automated image-based inspection for various applications. You can use these systems for quality control, automated inspection, sorting, and robotic guidance. If you are looking for a comprehensive quality inspection system, you have come to the right place.

A quick glance at our indigenous vision inspection system

We have an indigenous vision inspection system with a simple and easy to use interface. You can store all the inspection data with the help of the IPC function. The stored data can include recipe information, images of defects reports, audit trails, and a lot more.

How our indigenous vision inspection system can redefine your QC process

The vision inspection system is an all-in-one mechanism to inspect packaged items, their shape, and position. You can expect a quick inspection and sorting of packaged items. The system will automatically detect packaged items that are fit to pass or fail, giving the operator the cue on taking the appropriate action.

Various businesses from industries like healthcare, beauty care, FMCG, dairy, and specialty chemicals can use the vision inspection system to improve their quality check process.

An all-in-one inspection system for caps, labels, bottles, and wads

It is a comprehensive vision inspection system for quality control of all the manufacturing processes. Here’s what it will inspect.

- Bottles: Cuts, Spots, Holes, Marks, Scratches, Bottom Ballooning, Scratches.

- Caps: Spots, Holes, Shrinkage, Scratches, Cuts, Marks, Warpage, Short Mould, Excess Gate Point.

- Labels: No Labels, Carcode Check at front and back, Mispositioning, incorrect details, colour change.

- Wad: Damages, Shade Difference, No Or Reverse Wad, Foreign Particles, Dents, Scratches.